Radius gutters or curved gutters can most times be manufacture to accommodate regular hangers or to have custom made hangers installed.

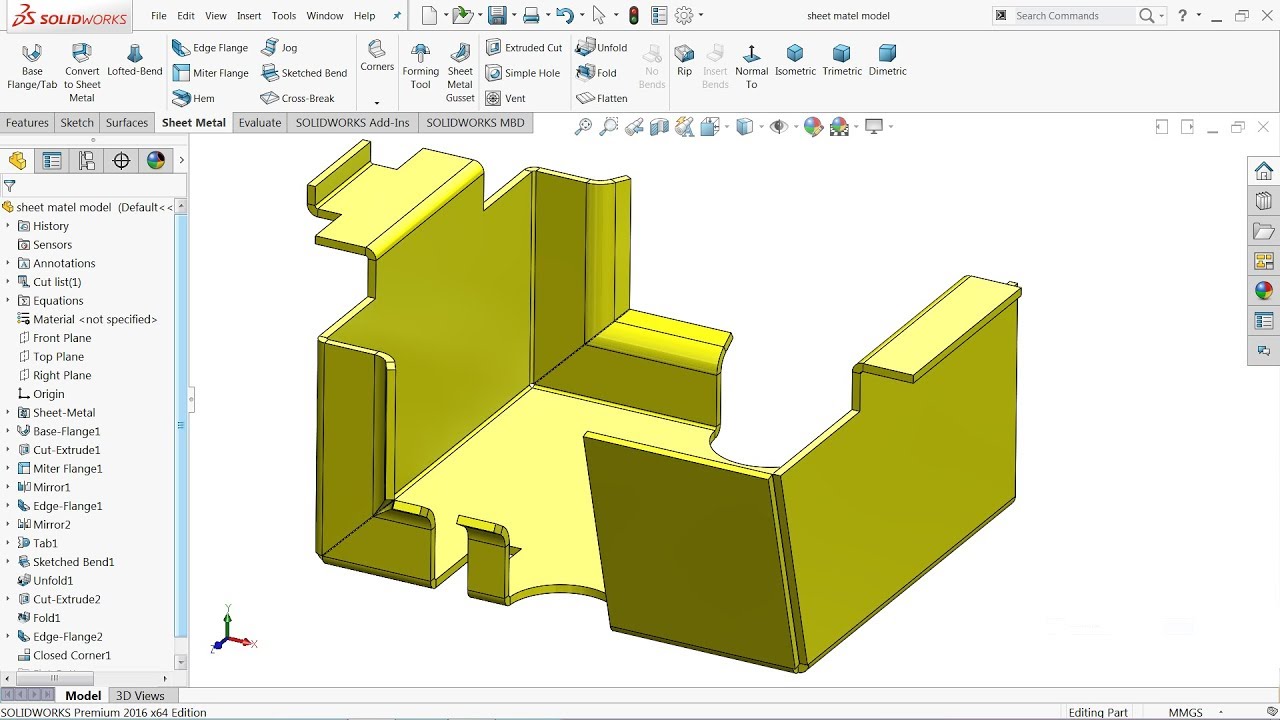

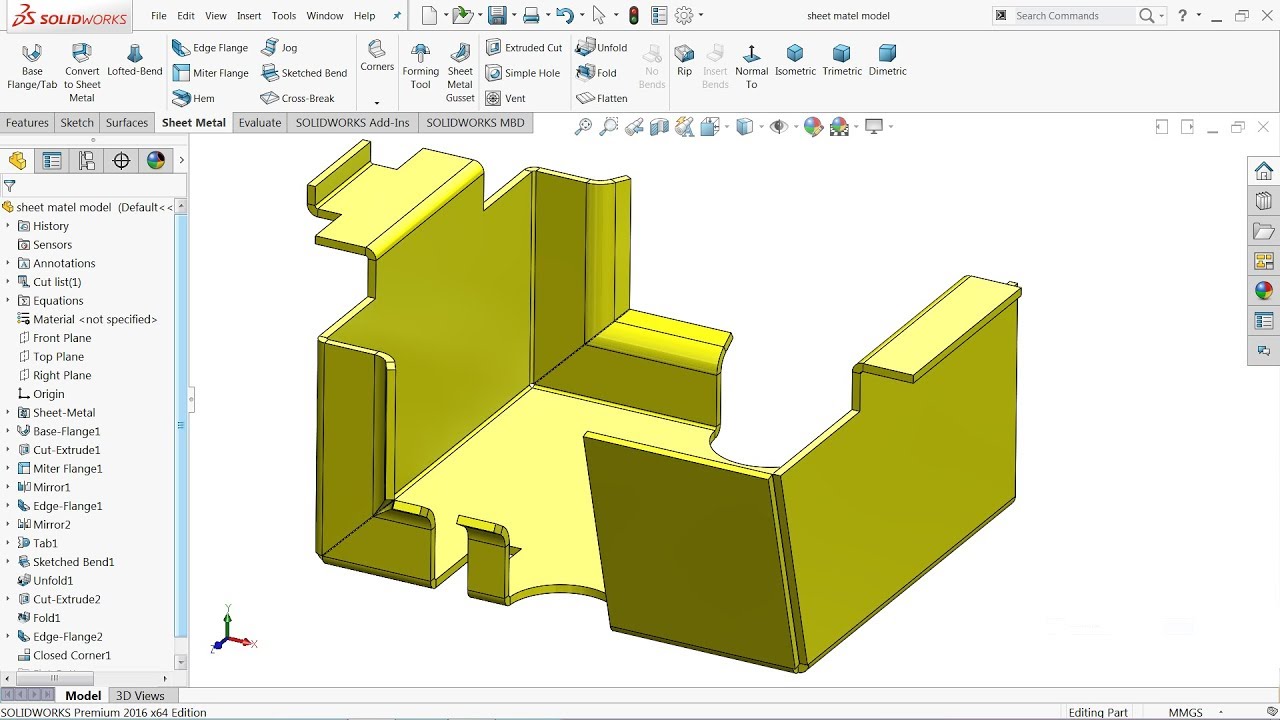

Curved sheet metal box design.

Always determine your material s strength.

The average hack requires at least one angled metal part and the best tool to make one is still the good ol press brake.

Different degrees of curvature can be achieved by using different tooling and bending parameters.

It saves time less de burring gives.

This helps in delivering the product at low cost and faster timelines.

Bending metal and bend radius.

You re done with diy planter container.

In the workspace add desired custom features as needed.

The most common profiles are half round k style box and brownstone gutters but we can also manufacture custom designed gutter liners and radius gutter liners.

Hems are created when you fold over the metal back onto itself.

Sheet metal enclosures and parts are bent with a press brake or a folder.

From the list select sheet metal box.

The metal typically cannot be formed into a true 90 degree edge but rather the corners have a radius as you can see in the diagram below.

To make things easy for my students i designed our classroom box so it would be able to work on the size of a standard 8 5 x 11 piece of paper.

Sheet metal boxes are two part enclosures made by cutting metal sheets and then bending the resulting parts using a press brake to form a box.

Enter the desired parameters and click ok.

Sheet metal design guidelines are followed to design quality sheet metal enclosures.

That s why we love it.

Open emachineshop cad and select file new.

The box i have my students create in class ends up being 5 5 x 2 x 3 5.

Use red sheet metal snips to cut panels for the short sides.

Therefore exceptions can be there for complex features design.

But when you re designing a sheet metal part add a few strength enhancing features to make sure your part lasts for generations.

Riverside sheet metal specializes in the custom fabrication of radius gutters.

Expand the wizards drop down.

This will prevent the box from coming apart once dirt is added inside.

The patterns for a cardboard box will look very similar to what you need to plan out for the sheet metal box.

Metal angle or metal wire could be an alternative to 2 4 on top if you prefer not to use it.

Following all sheet metal design guidelines is very difficult in the complex part.

When making sheet metal enclosure designs remember that they must be fabricated by clamping and bending.

Using wood screws attach one 2 4 on top.

It can be bent warped and folded easily.